The Pin Badge

Electroplating is the necessary process of each pin badges because of it would enhance the delicate outlook of the products, makes the goods to be more attractive for the customer. Sometimes, it's also very helpful to achieve and meet the concept of the original design. So It is always the electroplating that plays an decided role in the product quality positioning.

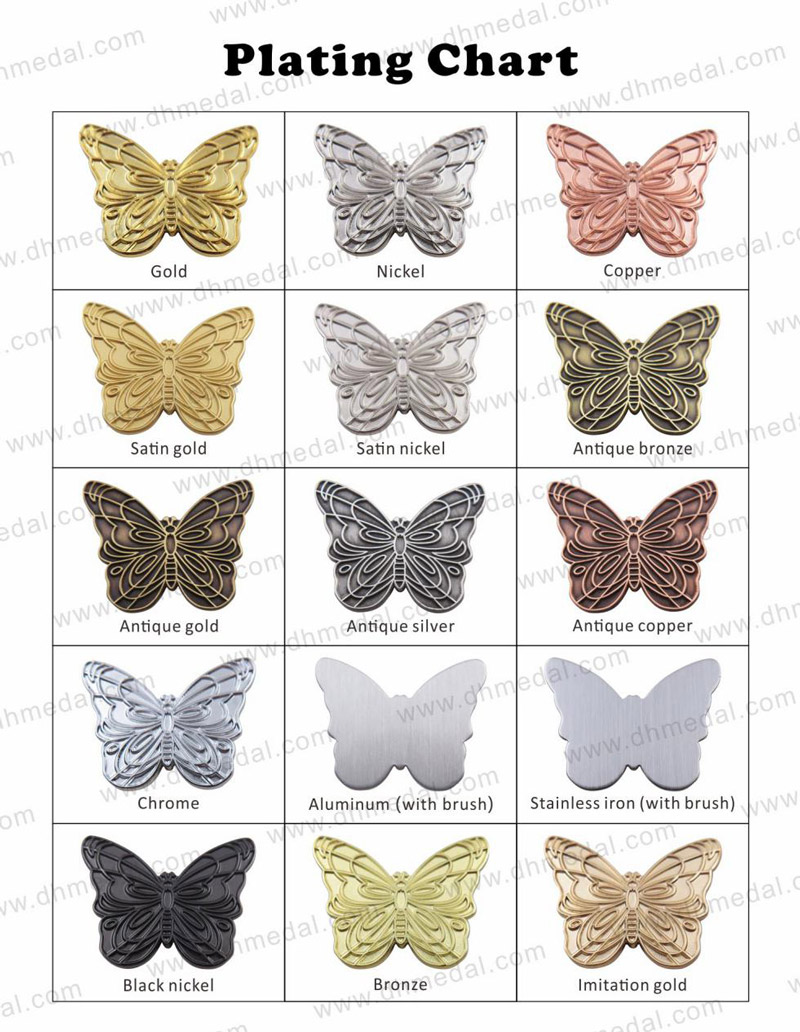

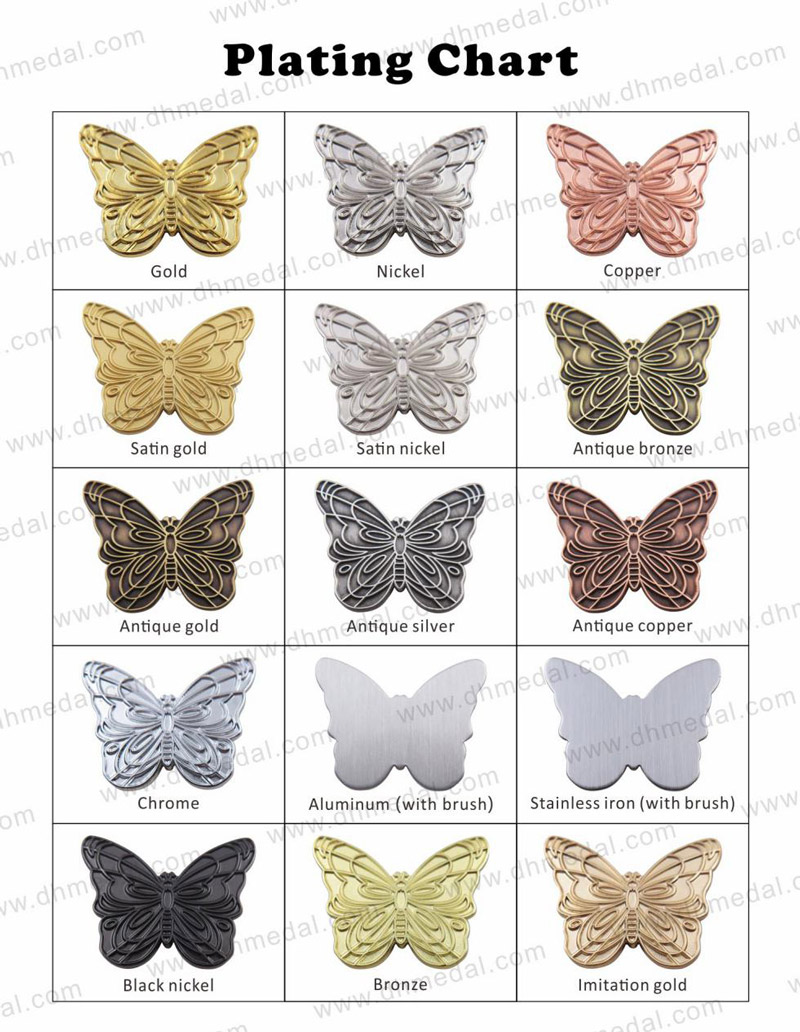

We have many options for badge plating. For example, genuine gold, imitation gold, bronze, nickel, silver, rhodium, red copper, black nickel, dyed black, genuine gold, imitation gold, antique bronze, genuine silver, imitation silver, antique nickel, antique copper, genuine gold, imitation gold, satin nickel, satin copper, and so on.

The choice of electroplating color, first of all is decided by the designer’s expectation for the product. Secondly, if the customer is not sure, our professional staff will choose the electroplating color which is closest to the original design and recommend accordingly.

In addition, how to ensure the plating quality?

You get what you pay for. Since the market competition is so transparent, the market rules have been more and more obvious. To ensure the quality of electroplating, on the one hand, the expertise and experience of the electroplating master and the electroplating plant are essential. FE has been in the badge industry for 36 years and owns its own electroplating workshop. What’s more, the electroplating master has been more and more experienced together with the company’s development. At the same time, in order to provide better serve for our customers, we have also updated our electroplating workshop to be a fully automatic one in recent years, which is unique in the Chinese badge industry.

To ensure the quality of the plating, we should ensure that the plating tank is clean so that it would not mix with different impurities. As our factory is our own electroplating workshop, we use separate bath electroplating for different electroplating colors. Each plating is treated separately. We are different from the outside electroplating factories. They have limited scale and limited orders of the same electroplating color, therefore, they have to constantly change the electroplating color in the plating tank. There is no doubt that its stability is incomparable to ours.

Before electroplating, the clarity of the product is also one of the important factors that affect the electroplating effect. We have strict quality control in every process. Because of the 36 years of good reputation in our industry, we are naturally trying to protect our reputation and will not allow any negligence to ruin it. Thus quality control is a very serious and important issue by us, which is out of the reach of the other factories.

Also, we use good materials for electroplating. Our company always adheres to the principle of open and transparent communication with customers. In electroplating, as for the material of gold, we have a clear distinction between real gold, imitation gold and bronze. Unpleasantly, there are many factories doing something dishonest. They take for granted that it is impossible that customers will use real gold to electroplate badges. So they choose to replace the gold with bronze or fake gold, but they describe the quotation just as "gold". On the one hand, bronze and imitation gold have a color similar to real gold, which is difficult to distinguish. On the other hand, many guests are not themselves engaged in the industry, they can hardly distinguish between bronze, imitation gold and real gold. However, this will inevitably lead to misunderstanding or unnecessary losses for customers who really need gold plating.

For the electroplating quality of a product, another important point is the impurities or pitting on the surface of the product. For different product application scope and positioning, customers can agree with us in advance different quality requirements standards. We have military quality and promotional quality to choose from. Of course, the price cost is certainly not the same. Thanks for your understanding.

So, where is your product positioned? Does it match your company's image positioning? When you choose a manufacturer, you should spend more time in examining the electroplating.

Here is just a little bit of sharing. We'll share more tips on how to choose the right plating color later.

Forever Emblem & Badge International Ltd.

Forever Emblem & Badge International Ltd.  CONTACT NOW

+86-769-2290-0190

CONTACT NOW

+86-769-2290-0190

E-mail to us

order@dhmedal.com

E-mail to us

order@dhmedal.com

English

English 日本語

日本語 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский Suomi

Suomi Svenska

Svenska

+86-769-2290-0190

+86-769-2290-0190

Sales Department, Building 1, No. 2 Lane 26, Xingguang Road, Xiansha, Gaobu Town, Dongguan, Guangdong

Sales Department, Building 1, No. 2 Lane 26, Xingguang Road, Xiansha, Gaobu Town, Dongguan, Guangdong  Facebook

Facebook  Twitter

Twitter  Pinterest

Pinterest  Linkedin

Linkedin